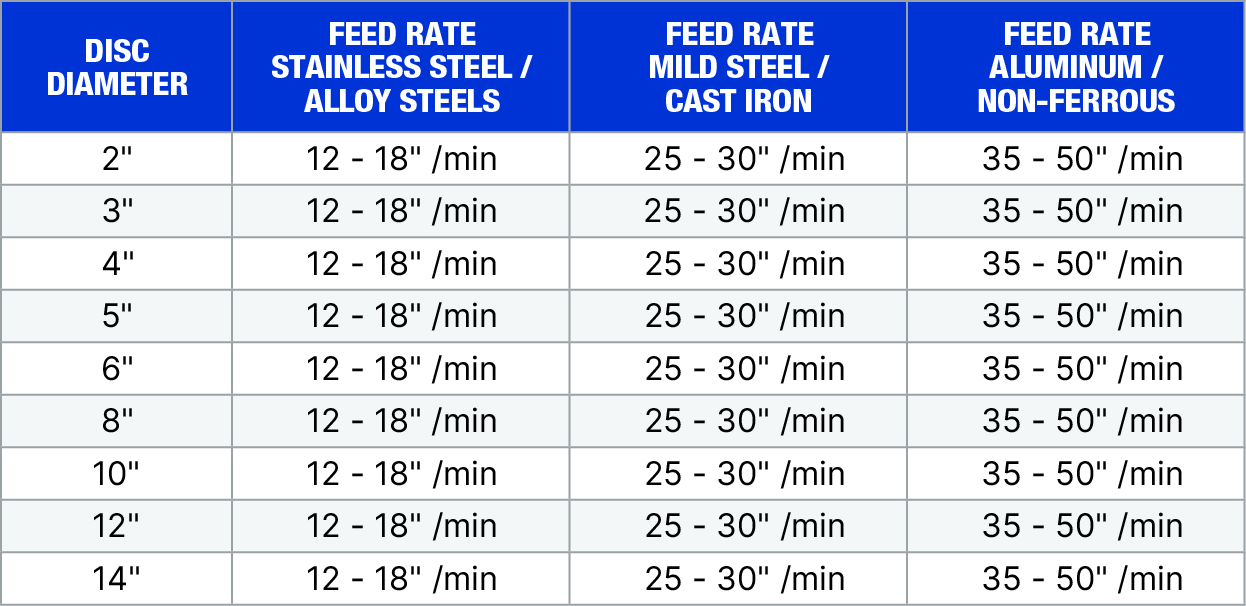

Abrasive Disc Brush Guidelines

Brush Guidelines

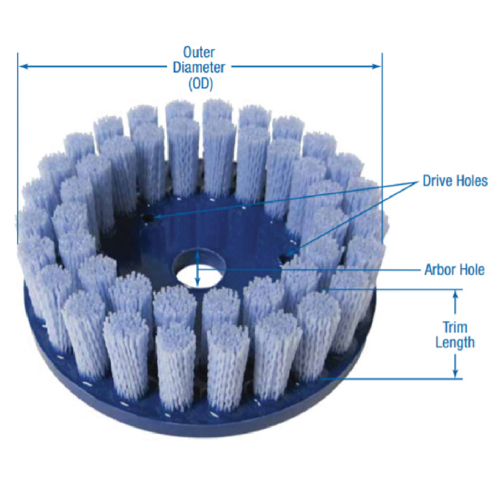

Outer Diameter: Overall diameter measured through the center of the brush from outside edge-to-edge

Arbor Hole: Arbor Hole is mounted to a tool or drive arbor. Arbors are driven by the spindle and provide the necessary length for the tool to reach the workpiece.

Drive Holes: A drive arbor has pins that mount into the brush. The pins mount into the locator holes and serve as drive pins for the brush.

Filament Trim Length: Length of Filament matters to performance and brush wear. For more flexibility choose a longer trim. For more aggressive brushing, choose a shorter trim.

Disc Brush Patterns

Tufted Pattern

Offers superior filament flexibility, ideally suited for parts with contours, grooves, slots or radius needs.

Teardrop Pattern

More filament strands than the tufted pattern while still offering some filament flexibility and designed for ease of coolant flow through.

Dense Pattern

Maximum filament density to apply consistent aggressive pressure for removal of heavier burrs. Suited for large flat surfaces.

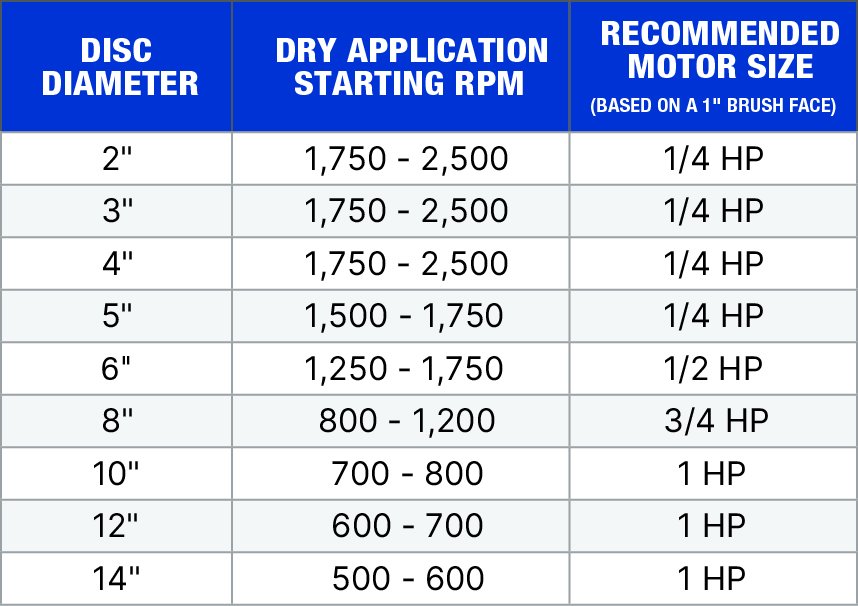

Recommended Operating Parameters

Abrasive nylon disc brushes work best at speeds allowing fairly deep penetration of the work piece into the brush filaments. Faster speeds do not typically work as well as slower speeds, since the maximum RPM listed on the brush is not the optimum working speed. A good rule of thumb is to stay below 2,500 SFPM in dry applications and 3,500 SFPM with coolant.

Disc Brush Types

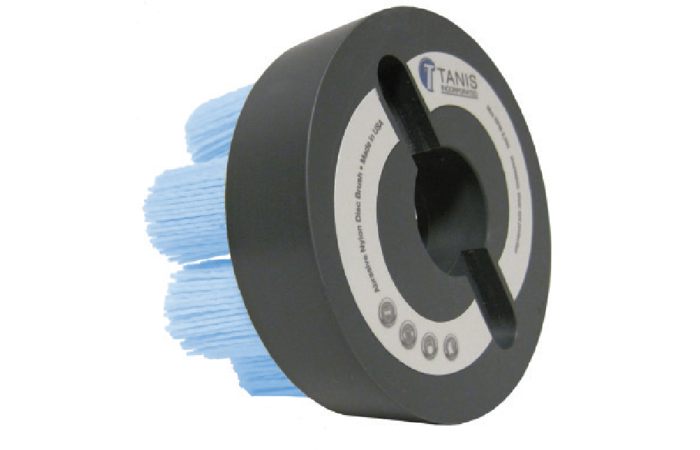

Disc Brushes

Disc Brushes are available in three different patterns and are ideal for flat part deburring, surface finishing and polishing. Brush diameters range from 4” to 10”.

Shell Mill Disc Brushes

Shell Mill Disc Brushes are designed with a built-in keyway for ease of mounting on a standard shell mill holder for deburring, blending and surface finishing. Brush diameters range from 2” to 10”.

Mini Discs

Mini Discs are designed with a dense filament pattern for aggressive finishing of smaller surfaces – deburring, blending and polishing. Offered in 2” & 3” brush diameters.

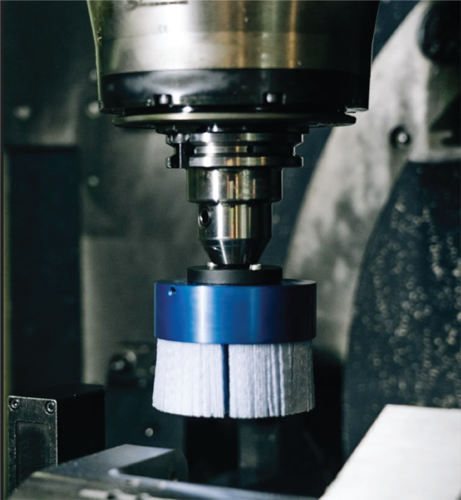

Abrasives in Action

Part Penetration (Depth of Contact)

Recommended starting depth of penetration rates for abrasive nylon disc brushes are .075"–.100" and a feed rate of 18” per minute.

Keep in mind, every machine and application differ so you’ll want to start with less depth of contact and a lower speed and increase slowly to find the optimal settings for your desired finish.

For consistent quality, make sure to inspect the finish after so many parts since the brush filament wears away during use. You’ll need to adjust the settings over time to continue achieving the same outcomes you expect.

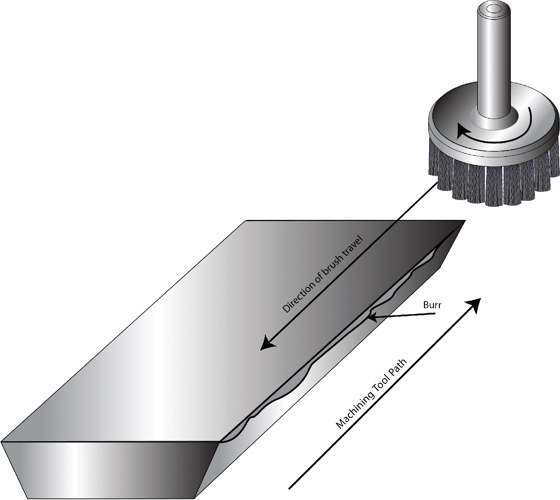

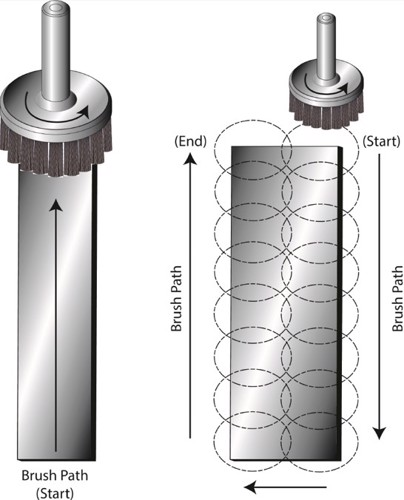

Brush Rotational Path

On the initial pass, the brush should be rotated in the opposite direction of the cutting tool that created the burr in order to effectively remove the burr. Rotating in the same direction simply pushes the burr down without removing it. The brush should overlap the edge of the part by 1” minimum to successfully reach the whole burr.

Recommended Brush Path

The ideal brush path is in the opposite direction of travel from the cutting tool that created the burr. The brush path should also be longer than the cutting tool path, to a point where the trailing edge of the brush is effective on reaching burrs at the end of the part. Lastly, to maximize the amount of filament that is striking the part, the center line of the brush should be offset slightly from the center of the part.